Manufacturing Inventory Reduction

Achieved Elusive Inventory Management Target

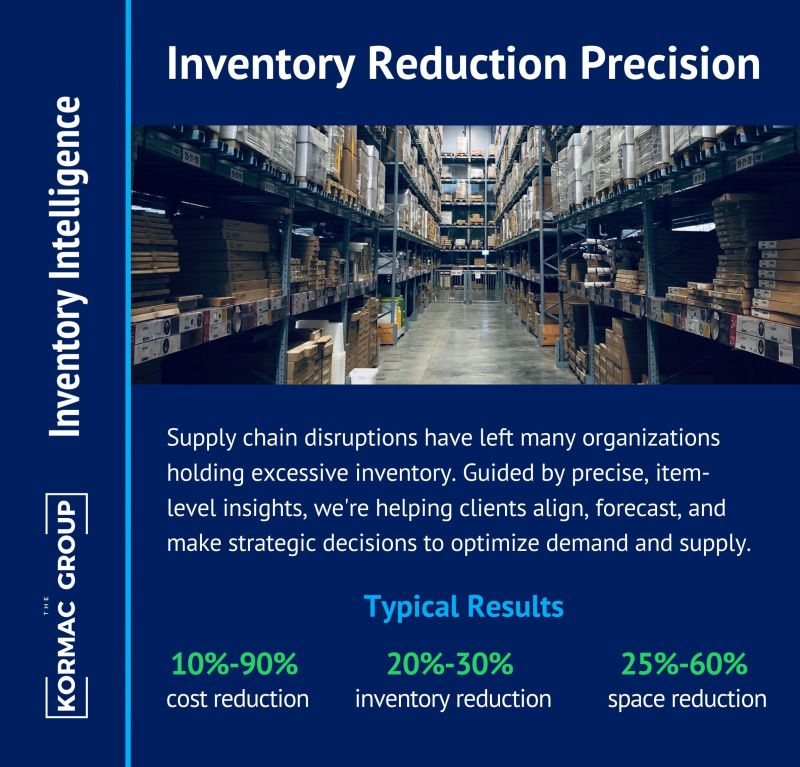

To improve cash flow while mitigating risk, many companies are reevaluating their approach to inventory management. Excess materials and persistent shortages remain despite the overall recovery from pandemic constraints. When times were tough, gaps in inventory management discipline magnified the impact of constrained supply chains. As conditions improve, discipline gaps still leave...